There are many types of inspections that are carried out in different industries but in most general terms they are defined as organized examinations or formal evaluations of something or somewhere.

They involve routine checks or critical evaluations and are conducted to assess whether the subject is in working order or up to the required standards. Here, we’ll take a look at some of the most common and effective inspections in quality control (QC), why they exist and what the benefits are.

Overview of inspections in quality control

In quality control, buyers in international trade need inspection services to verify product standards and quantity according to predetermined specifications. Companies should partner with a trusted third-party inspection service for the best results. It makes sense to invest to ensure the highest standards for your products and services in the ever-changing global market.

Different types of QC inspections

Depending on your product and industry, you’ll need a certain inspection service when searching for quality solutions. But there are some common one you should definitely know about if you’re in the business of trade and manufacturing.

Below is a selection and along with their respective role of inspection in quality control explain. Types of inspection and methods of quality control inspections differ for a reason so it’s good to know the details.

Sample Checking

Sample checks involve selecting a small number of items from a bigger batch or lot to check a range of their specifications such as appearance, workmanship, safety, functions, etc. prior to mass production. Basically, a sample of the products are extracted from the bunch and inspected for quality, rather than the whole lot.

Inspectors will be looking for potential defects and will compare the physical objects and products to design plans and drawings to ensure the correct measurements have been met. Style and color are other things which can be checked as well as shipping marks and packaging.

Pre-Production Inspections (PPI)

As the name of this type of inspection suggests, pre-production inspections are carried out before production begins to assess the quality and quantity of raw materials and components. This type of inspection is great for when you begin a new relationship with a supplier. You can ensure they are using the right type of materials for your production and implementing the right processes to deliver the product you expect.

But also, a pre-production inspection can help you avoid delays in your supply chain and the delivery of a production. After all, no one likes missing a deadline. Product timelines and shipping dates are as important as the product quality and communication with your supplier is key. A pre-production inspection helps you to identify issues at an early stage before it becomes too late.

During Production Inspection (DPI)

During production inspections are also sometimes known as DUPRO and these are conducted while the production is in progress. They are meant for products that are in continuous production and have strict requirements for on-time shipments and as a follow-up when quality issues are found prior to manufacturing during pre-production inspection.

Only 10-15% of units are completed when this inspection is carried out giving you a good idea of the direction of your product at an early stage. Once problems have been rectified, checks are made again to ensure everything is suitable and as it should be prior to pre-shipment inspection. Inspectors will produce a full report together with supporting imagery to provide you with comprehensive information and data.

Pre-Shipment Inspection (PSI)

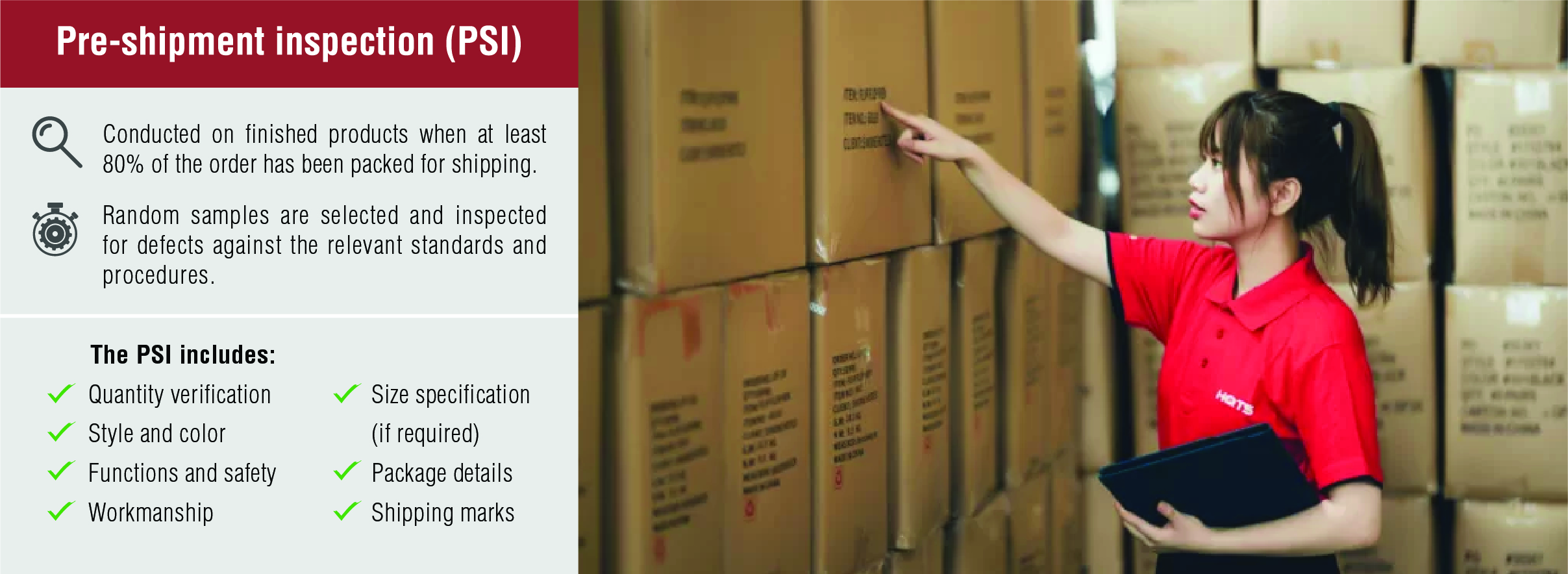

In short, the meaning of a pre-shipment inspection is that it is a method for checking the quality of goods before they are shipped. This type of inspection’s purpose is to check that a production aligns with the specifications of the buyer or purchase order/letter of credit. But at what point is a pre-shipment inspection conducted exactly?

They are carried out on finished products when at least 80% of the order has been packed to ship. Samples are selected at random to take part and the inspection is done according to standard acceptable quality limits or customer requirements. PSIs are especially good for overseas buyers to stay on top of differing national standards and requirements and an increase in fraudulent trade conduct.

Piece by Piece Inspection (or Sorting Inspection)

This kind of inspection involves thoroughly checking each and every item to evaluate a range of variables. These can be things such as general appearance, workmanship, function, safety, etc. and inspections can be done pre- or post-packaging. The Piece by Piece inspections are carried out on 100% of goods. Upon completion, all products which pass inspection are then sealed and certified with an HQTS sticker to ensure that every piece included in the shipment meets your specified quality requirements.

Metal Detection

Needles being left in garments can be a serious issue if proper metal detection procedures aren’t carried out. That’s why metal detection is an essential quality assurance requirement for the garment industry. Sewn items could have needle fragments or undesirable metallic substances embedded.

Textile accessories during the manufacturing and sewing process could be left in fabrics that may cause injury or harm to end consumers. The application of metal detection and X-ray detection systems are deployed at various points during the manufacturing and sewing process, to ensure detection at all potential stages of the process.

Loading and unloading supervision

This kind of inspection is the process of monitoring the entire loading and unloading of goods to ensure your products are handled professionally. Supervision of the whole container loading and unloading process to your desired location can be arranged, wherever you’re shipping to and from.

The inspection and supervision process includes an evaluation of the condition of the shipping container, verification of product information; quantities loaded and unloaded, packaging compliance and overall supervision of the loading and unloading process. It’s an inspection service that’s signed, sealed and delivered with quality assurance guaranteed.

Quality inspection benefits

Not only do quality inspections allow you to keep an eye on what’s going on at the factory when you’re not there, they also ensure your products and shipment is being prepared correctly. Poor quality can naturally be detrimental to your bottom line and brand reputation.

That’s why it makes sense to increase visibility within your supply chain and ensure things run as smoothly as they can. Your duty is to keep your promise of a quality product to your customers and buyers which means inspecting your products and processes for potential flaws. Quality inspections reduce the risk of you.

About HQTS

No matter what your industry is, from apparel textile to toys, children’s products or food, HQTS is ready to service all your inspection needs. With over 25 years in the business, we are dedicated to helping you meet the quality, safety and ethical standards you demand throughout your supply chain. Our many service locations and professional inspectors are prepared to be your one-stop-shop for factory audits, production monitoring, pre-shipment and sorting inspections, and everything in between. Contact us today to find out how we can help you navigate your current quality control challenges.