Home > AQL Calculator

AQL Calculator

Acceptable Quality Limit (AQL) sampling is an effective way to perform quality assurance on an order of manufactured goods. By inspecting a selected sample, AQL helps your business identify potential defects, reducing risks and ensuring your products meet the standards before officially accepting it.

When placing orders, it’s essential for your company to evaluate the level of product quality and establish a clear method for ensuring those standards are met. Effective quality control minimizes risks, saves money, and streamlines production. By implementing a strong quality control plan, you gain better control over your suppliers, leading to increased bargaining power and stronger brand protection for your business.

Give our AQL simulator a try to find the perfect sample size and acceptance number for your next inspection.

HQTS Quality Inspections AQL Calculator

AQL Sampling Explained - HQTS Video

How is AQL calculated?

First, the sample size is determined based on the total batch size. The sample is then inspected for defects, which are categorized as critical, major, or minor. Using the AQL tables (Table 1 and Table 2 below), inspectors find the acceptable number of defects for each type. You can also use an AQL simulator, like ours above, to do the task for you.

For example, if you’re inspecting 10’000 phone chargers at a general inspection level II with an AQL of 1.5 for major defects and 4.0 for minor defects, you can input this into the AQL simulator to see how many defects are acceptable in your sample.

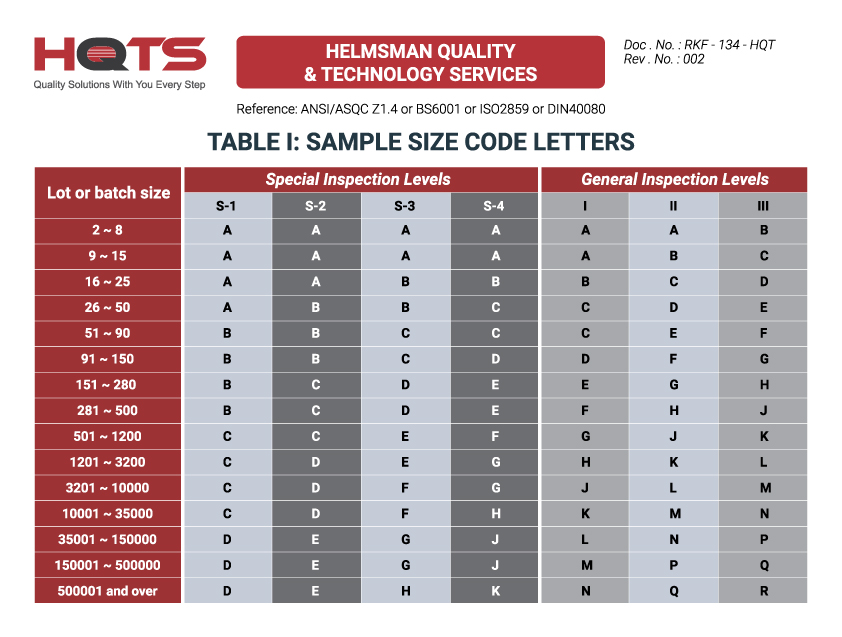

Table 1: Sample Size Code Letters

The most commonly used standard is the AQL Table 1 (below) which is used as a fundamental tool when carrying out quality control inspections.

The AQL Table makes it easy for the buyer, manufacturer and quality control provider to come together in agreement on quality inspection standards. This table contains rows for various batch sizes and columns for the different inspection levels. By finding where your batch size and inspection level intersect, you can determine the code letter.

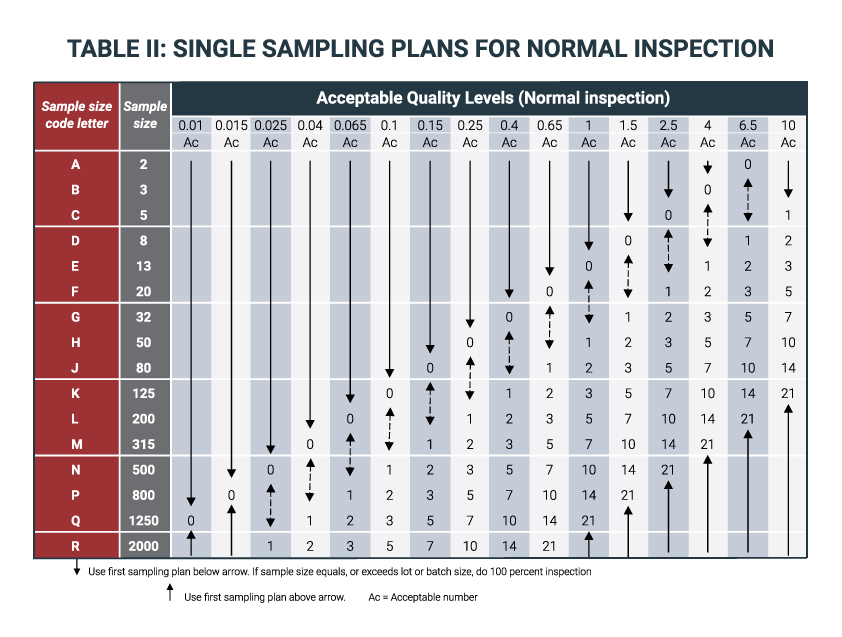

Table 2: Single Sampling Plans for Normal Inspections

Once you know the code letter, you can then move on to table 2.

This table tells you the sample size based on the code letter you obtained from Table 1. Table 2 includes single sampling plans for normal inspections and the check marks on the table show how many products have passed whereas, the cross shows how many have failed. The up arrows mean you should use the sample size listed above the arrow. If the arrow matches or is bigger than your batch size, you should do a 100% inspection or a piece-by-piece inspection.

For down arrows, use the first sample size listed below the arrow.

What is an AQL Inspection?

AQL (Acceptable Quality Limit) is a standard used to determine whether a product batch meets the required quality by inspecting a sample rather than the entire batch.

It’s based on international standards (ISO 2859) and is widely used to decide if a product order is acceptable or should be rejected. AQLs can be set for a percentage or number of critical, major and minor defects. The inspector checks a sample of the shipment for issues with performance, usability, functionality, and appearance.

If everything meets the standards, a certificate is given to confirm the product quality.

Critical Defects

A 0% critical defect rate is typically required, as critical defects are unacceptable. They can pose harm to the end user, lead to non-compliance with local regulations, or cause product failure. Critical defects are the most severe among the three types of defects. These flaws make a product entirely unusable and expose companies to avoidable risks, including product liability concerns, legal actions, and potential recalls.

Major Defects

A major defect rate of up 2.5% is generally acceptable. Major Defects have a negative impact on the product’s performance, functionality and appearance and often represent noticeable issues easy to detect by the final user.

Minor Defects

A minor defect rate of up to 4% is generally acceptable. These defects represent small deviations from product specifications that most buyers would still tolerate. Minor defects do not affect the product’s performance or functionality and are often unnoticed by the end user.

What are the benefits of AQL quality control inspections?

AQL can be a more practical alternative to testing every product in a batch.

While testing everything is manageable with small volumes, larger orders make this difficult due to time and cost constraints. AQL has been a trusted method for years, though it doesn’t guarantee a defect-free result since some issues may go unnoticed.

AQL will simply allow you to select the percentage of defects that you are willing to accept and can be a sensible option when it comes to gaining valuable insights about the products in your supply chain.

About HQTS

AQL sampling is a practical and effective way to perform quality assurance on an order of manufactured goods to reduce the risk prior to accepting an order. With nearly 1,500 experts across 40+ countries, HQTS brings extensive industry knowledge and experience to support your quality needs.

HQTS is a third-party inspection company with over 25 years of experience in quality assurance. We can help you conduct AQL inspections globally, helping you maintain high standards no matter where you operate. Contact us to find out how we can help you today.