Quality control in steel products is extremely important. The steel fabrication process demands attention to detail and an understanding of the many variables that come into play.

When sourcing steel products from another country, you often have no control over the production process and must rely solely on your supplier. Steel inspections can help to reduce risks and ensure that the products meet your quality standards.

In light of this issue, we’ve created an insider guide from our clients’ cases packed with steel quality inspection strategies to reduce your risks when you buy steel from China, India – or anywhere else in the world.

Why Is Steel Quality Inspection Important?

Quality inspections of steel products are important to ensure that the products you’re purchasing meet industry standards and customer-specific requirements. Steel inspections can often help you identify faults or irregularities in the material – even before you receive the products from your supplier- saving you both cost and time.

But not only does it ensure the reliability and safety of the steel, but it can also verify that the produced steel products use a particular grade of steel and meets agreed-upon standards set by industry bodies such as ASTM (American Society for Testing and Materials) or AISI (American Iron and Steel Institute).

What to Consider When Buying Steel Abroad?

The first step is to understand the technical requirements of the products that you’d like to purchase, and be aware that each country has its own standards for steel production. Make sure your supplier can meet your technical requirements, despite what steel standard they have.

What Are the Common Steel Standards?

There are numerous steel standards, each with its own unique grading system and levels. Some of the most common include:

- American Society for Testing and Materials – ASTM

- American Iron and Steel Institute – AISI

- Society of Automotive Engineers – SAE

- Deutsches Institut für Normung – DIN (German Institute for Standardization)

- European Committee for Standardization – EN

- Japanese Industrial Standards – JIS

- China National Standards Committee – GB

Steel Vendor Selection: How to Audit Steel Suppliers

One of the most critical moments in the selection of steel suppliers. Most of the steel producers are located in China, India, Japan and Brazil, and their factories are located thousands of miles away from you. It is important to find a supplier who can meet your needs in terms of quality, specifications, delivery time, and price.

How to Check the Steel Factory?

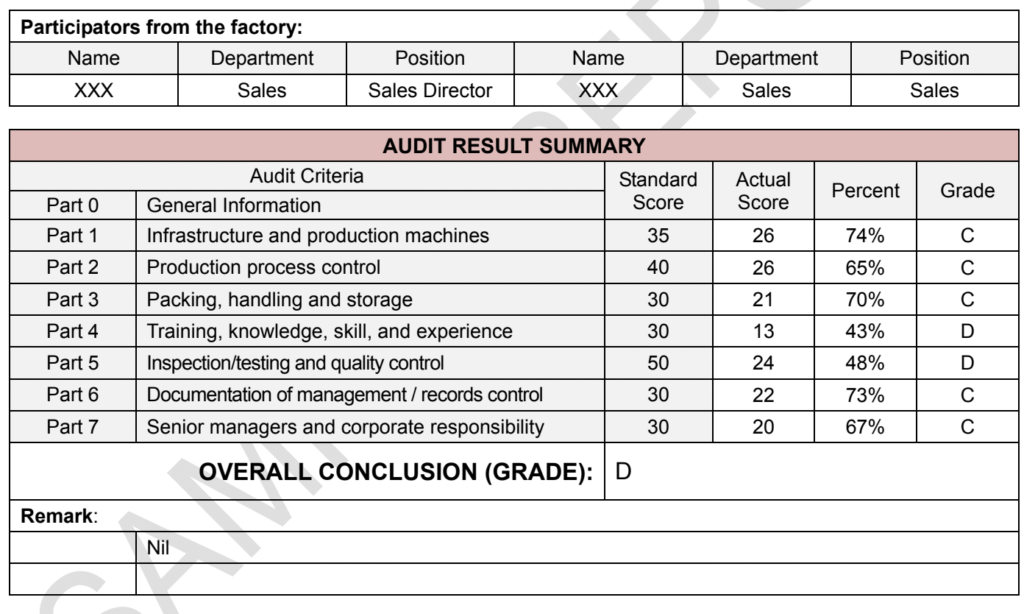

If the steel vendor you’ve chosen is a manufacturer, then you should consider doing a factory audit. A factory audit often includes: checking the manufacturer’s basic register information and background, bank information, existence and production capability, quality control and management system, human sources and more.

An image of a factory audits summary, click here to see the factory audit sample report.

How to Check a Steel Supplier?

Be aware that many steel traders try to pass themselves off as a manufacturer, especially in China. If you’re questioning whether your vendor is a trader or manufacturer, consider conducting a supplier audit to review the company’s registration information and background.

Steel Supplier Versus Steel Manufacturer, What Is the Best Option?

Both steel manufacturers and trading companies have their advantages and disadvantages.

Advantages and Disadvantages of Buying from Steel Manufacturers

For still mills, they have invested heavily in many fixed assets. Hence, it’s less likely that they would risk cheating. They can also control the production of the order by themselves, making it more likely that they will produce the goods on time and as per the specifications and standards.

On the downside, metal manufacturers often require a higher minimum order quantity and can’t produce multiple goods at the same factory.

Steel Trading Companies Advantages and Disadvantages

The advantages of dealing with steel trading companies are that they are more flexible than manufacturers. For example, they are more likely to collect orders with many specifications and low quantities and can offer alternatives to you.

They are also very familiar with the market, have many sources and can communicate well with steel mills to resolve problems and find the products you require.

Aside from having little to no control over the actual productions, the main disadvantage is that the company may use your down payment to find materials from steel mills and:

- Wait for the market to turn to get lower prices, which can influence their on-time delivery

- Substitute your steel products that are of a foreign standard with ones that have a similar domestic standard.

- Increase the price after your down payment and demand you pay the price difference.

Tips for Selecting the Best Steel Supplier

Below are some tips for choosing the best supplier for your steel products.

- Opt for steel mills – Purchase directly from the manufacturer if your order meets the minimum requirement of order from the steel mills, as they are less likely to cheat on you.

- Beauty can be a red flag – If a supplier has an amazing website, but it’s only in English, and the contact information is just a personal cell phone number, that should be a concern to consider.

- Deposit payment – Before giving a company any money, we strongly suggest you double-check them through an audit, especially if something doesn’t feel right.

- Be cautious of low prices – Don’t be fooled by cheaper steel options; the lower price is usually indicative of a lower quality product.

Steel Inspection: What Quality Inspection Is Best for Steel Products?

There are four primary types of quality inspections used in quality control; however, when it comes to steel products, the most required inspections are often pre shipment and loading supervision for steel quality control.

The Steel Inspection Checklist: Pre Shipment Inspections

The pre shipment inspection (PSI) of steel products is conducted on a random sample of finished goods and packed on-site to ensure that the products comply with your specifications, or a full inspection (checking all products). The inspector will look at different parameters, including:

1. Style and Quantity Check:

Check the actual weight of the steel by calibrating the weighting apparatus and quantity check the pieces by counting (especially useful for plates, sheets, tubes and bars).

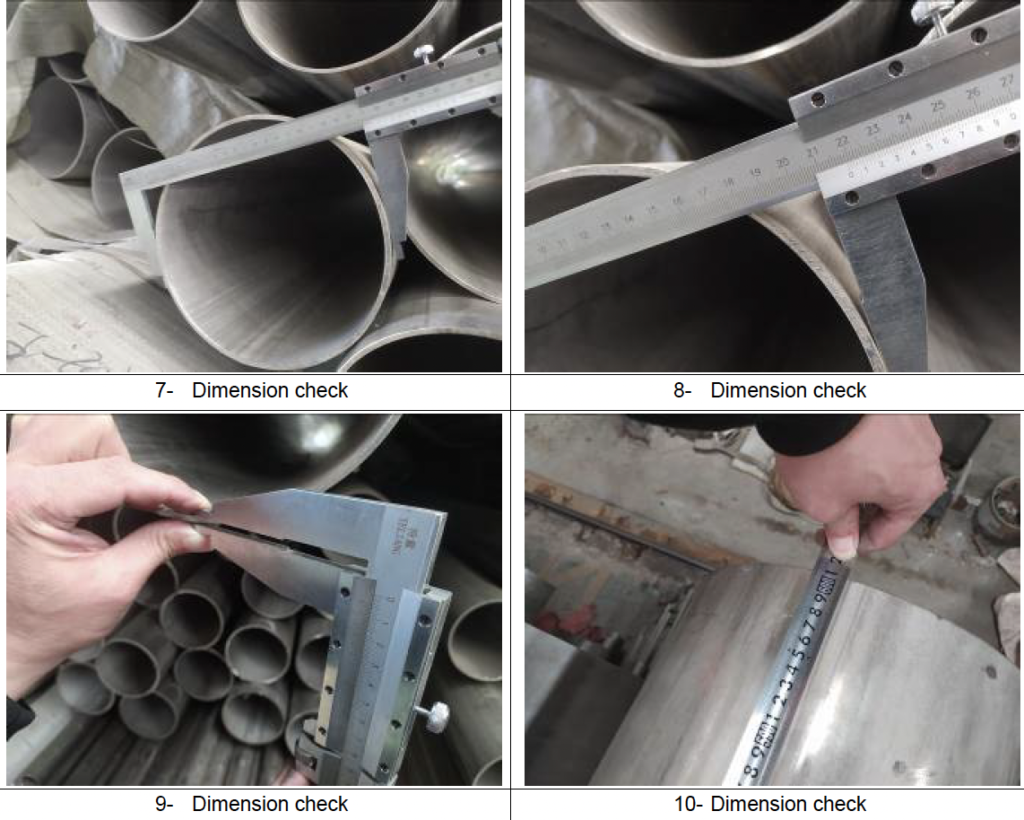

2. Steel Dimension Check:

Verify that the dimensions align with the agreed specifications by assessing the following:

- Plates and Sheets Coils: thickness, width

- Bar: diameter

- Pipes: Outside diameter, wall thickness, straightness, ovality and more.

3. Visual Inspection of Steel

Check the workmanship of the produced goods to identify using a visual inspection. This will tell you whether there are any defects such as dents, scratches, uneven weld beads, underfill of weld materials etc. The acceptance of these imperfections is per the applicable standard.

Other Important Pre Shipment Inspections

- Check the manufacturers Mill Test Certificate (MTC).

- Check the chemical composition using a PMI Spectrometer.

- Check the shipping mark and packing check.

Steel Lab Testing Inspections

1. Chemical Composition Test – Used to determine the chemical composition of the steel and measure its quality.

2. Mechanical Property Test (Yield Strength, Tensile Strength, Elongation) – Evaluate the material’s tensile strength, yield point, and elongation percentage.

3. Hardness Test – Check the material’s resistance to local penetration.

4. Ultrasonic testing (UT) of steel – Detect if there are any flaws or defects in the material.

Risks During and After Steel Pre Shipment Inspection

Here are some of the main risks that are associated with a pre shipment inspection.

- Don’t forget the check the steel grade, the supplier may substitute your steel products that are of a foreign standard with those of a similar domestic standard.

- It’s important to test the chemical composition to check the authenticity of the materials and compare the testing result with the MTC. For example, some materials may be of lower grade materials (for example, SS201 instead of the required SS316).

- Ask the supplier to package all the materials on-site when the inspector is present so that they do not try to lower the quantity, especially the coils, which cannot be counted by pieces, after the inspection. Ask the inspector to stick or sign on the package to prevent someone from opening and repackaging the materials.

- Be aware that some machines may be tampered by the supplier and may give inaccurate readings, especially for those that are harder to calculate on-site, such as steel coils.

Check here one HQTS Steel Preshipment Inspection Sample Report

|

What Is a Loading Supervision Steel Procedure?

Steel products are of high value. Unfortunately, some suppliers may cheat to make an extra profit. Once the pre-shipment inspection is complete and the inspector has left, your products may still be at risk for replacement or having the quantity reduced by the supplier.

This is where container loading supervision is useful. A loading supervision is conducted to ensure that the cargo has been properly loaded into the container. This inspection includes:

- Check the quantity and weight.

- Check the package and label.

- Check the internal end external conditions of the container.

- Supervise the loading process and the placing and fixing the products in the container.

- Sealing of the container and witnessing the container leave.

Tips: Try to witness the container leave the factory after loading and record the license tag of the truck and the container number. Confirm with the driver whether it’s from the shipping company or the agent.

Conclusion Steel Inspection Checklist and Tips to Reduce Risks Quality Risks (Insiders Guide)

The steel market, especially in China and India, is complex, as there are small traders who pose as fraud suppliers. However, most of these suppliers are reliable businesses. Having said that, it’s important to know the risks associated with buying steel abroad.

To mitigate risks, we recommend conducting a supplier audit or factory audit on the businesses, combined with a pre shipment inspection and loading supervision.

Do you need help with steel inspections? Reach out to us at HQTS. We are an internationally recognised and CNAS ISO17020:2012 accredited quality control company that has helped over 50,000 clients to prevent quality issues in their supply chain and ensure compliance.