Imagine you’ve just received a large shipment of food products from a supplier. As you start inspecting the products, you notice that some of them are damaged, not properly labeled, and do not meet the required quality standards. It’s a nightmare for any food business owner, and it could have been prevented with a pre-shipment inspection.

Food quality control procedures, such as pre-shipment inspections for food are important for verifying compliance with standards. In this guide, we’ll highlight the key areas of focus during a PSI inspection for food products.

Importance of Pre Shipment Inspection for Food Products

There are several key reasons why pre shipment inspection is important for food products:

- Compliance with regulations: The PSI inspections for food can help you verify that your supplier meet requirements for food safety, labeling, packaging, and hygiene.

- Quality assurance: Verify that the inspected food products meet specifications and conform to international quality standards. Subsequently, ensuring the products are of high quality and free from defects, such as contamination, improper labeling, or packaging issues.

- Dispute resolution: Pre shipment inspections provide a clear and objective assessment of the quality and safety of the food products. A part from this, these services are often performed by impartial third party inspections agencies.

What Is the Process of Food Pre Shipment Inspection?

Let’s explore the key steps involved in conducting a pre-shipment inspection for food products:

Quantity Verification

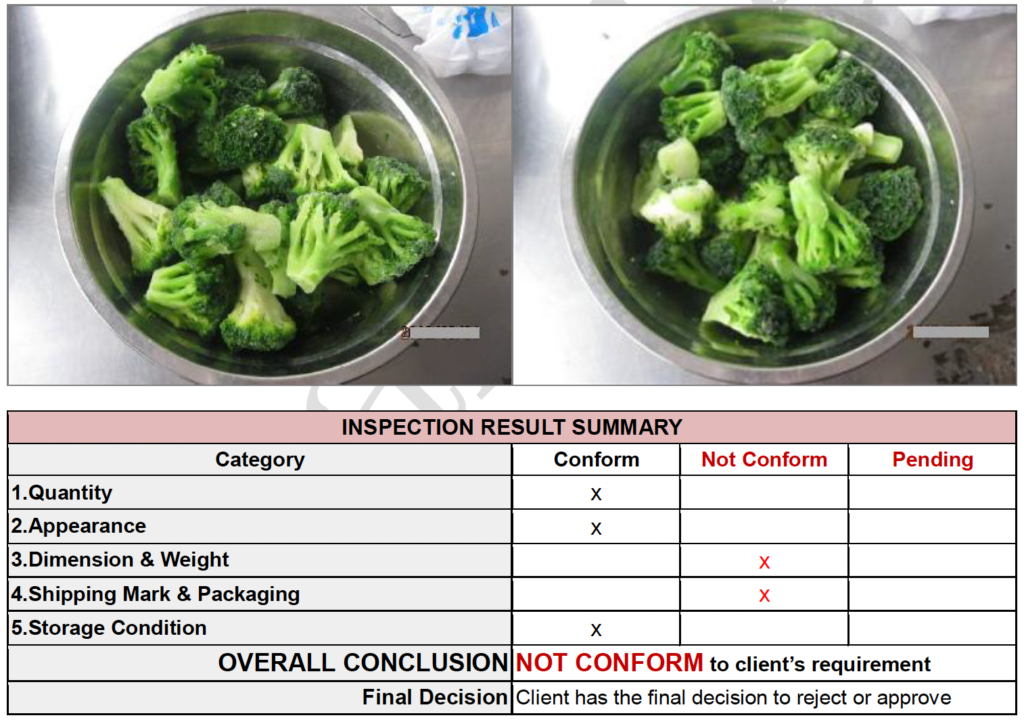

Verifying the quantity of food products is a crucial step in the pre-shipment inspection process. The inspector will compare the order quantity with the buyer’s purchase order, which may involve counting units or boxes, or weighing the products with calibrated scales or equipment to ensure accurate quantity verification.

Overall Appearance

The inspector will evaluate the overall appearance of the food products, including their color, condition, size, and shape. Special attention will be on visually inspecting the vegetables, fruits, rice – or whatever product is inspection – to verify that they’re free from visible damages or abnormalities.

Dimensions and Weight

The inspector will use measuring tools to assess the length, width, and height of the food products or weigh them. These measurements will then be compared against the specified size requirements as per the purchase agreement or contract.

Shipping Marks and Packaging

The inspector will examine the food product’s packaging to ensure that it’s in good condition and suitable for the type of food being shipped. During this process, the inspector checks for markings such as product name, quantity, and country of origin, while also evaluating compliance with applicable regulations and standards.

This thorough assessment helps to ensure that the packaging meets all requirements and safeguards the quality and safety of the food products during transportation.

Storage Condition

The inspector will check if the food products have been stored properly in line with industry standards, including temperature and cleanliness. This may also involve reviewing record-keeping practices to ensure that proper documentation, such as temperature logs, product rotation records, and other records, is maintained.

Note that specific inspection criteria may vary depending on buyer requirements, destination market, and the type of food products being inspected.

Choosing the Right Inspection Company

Selecting the right inspection company is crucial to ensure the effectiveness of pre shipment inspections. Here are some criteria to consider when choosing an inspection company for food products:

- Accreditation and expertise: Look for inspection companies that are accredited by reputable organisations and have expertise in food product inspection.

- Inspection scope and capabilities: Consider the scope and capabilities of the inspection company. An ideal inspection company should have the capability to conduct inspections at different stages of the supply chain, ranging from production to packaging and loading/unloading.

- Reporting and communication: They quality control company should provide detailed and timely inspection reports, and be able to accommodate your inspection requirements and schedule.

Conclusion

In summary, pre-shipment inspections provide a cost-effective solution for mitigating risks associated with sourcing food and agricultural products from suppliers. HQTS, with our global coverage in over 80+ countries and a team of experienced inspectors, can be your partner for food product inspections. Our inspectors can be dispatched within 3 days and we can tailor our inspection to meet your requirements. Contact us today for a free consultation!