As a business owner, there is a great deal of risk whenever you’re dealing with a new supplier. Is their business legitimate? Will they be able to meet your quality standards? The best way is to evaluate your new suppliers through factory audit services.

In this article, we’ll look at what general third-party factory audits cover in industrial goods and how they can help you reduce risks.

What is a China Factory Audit?

A third-party factory audit in China provides a more comprehensive evaluation of a supplier’s capabilities compared to supplier audits. These audits generally focus on verifying whether your supplier meets legal obligations, as well as its ability to consistently produce goods that conform to your quality standards. These audits are conducted by third-party organisations such as independent third-party quality control companies.

Why are Third-Party Factory Audits Important?

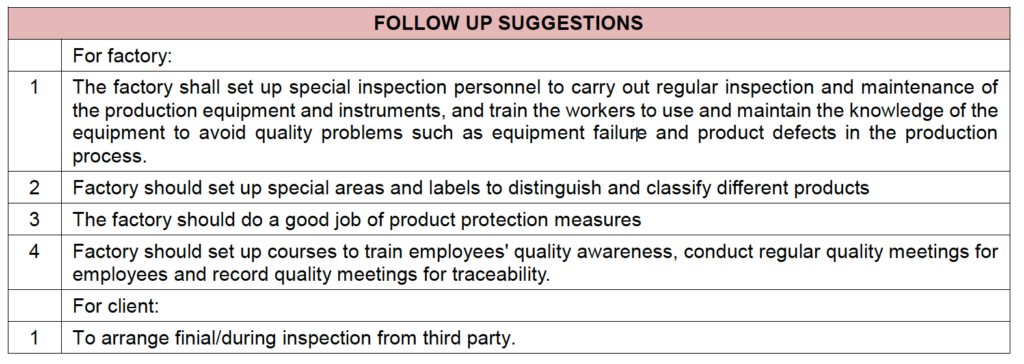

Third-party factory audits are crucial in verifying whether or not a supplier can consistently meet your quality standards and are often an important step in a quality vendor evaluation process. These audits will give you an unbiased evaluation of a supplier’s capabilities, identify potential risks, and can also include suggestions and provide recommendations for corrective actions.

By conducting a factory audit, your business can make an informed decision about whether or not the supplier is reliable and can uphold your quality standards.

How Do You Perform a Factory Audit in China?

It’s important to note that no factory audit fits all sizes of businesses and product categories. This means that the elements of a factory audit checklist may be customised to a client’s specific requirements or product category. Below are some steps involved in third-party audit of valve factory.

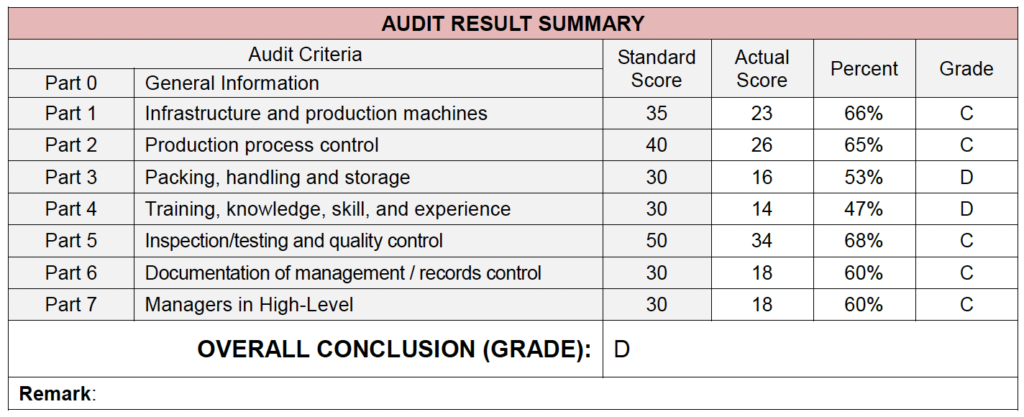

General Information

The first step in a third-party factory audit is to gather general information about the factory. These generally include its ownership, location, size, certificates, and more. This will give you an idea of the factory’s legal status and whether it’s operating within the country’s legal framework.

Infrastructure and Production Machines

The factory’s infrastructure, such as the buildings, layout, and equipment/machinery, is examined to ensure that they’re maintained regularly to ensure their continued process capability.

Production Process Control

The inspector will also check the company’s production processes, including examining the process flow, working instruction, workers’ operation, and more to ensure they’re efficient, effective and comply with relevant quality standards.

Packing, Handling, and Storage

The inspector will check whether the goods are adequately protected and stored in the right conditions. As well as checking the labelling and marketing system. Some key concerns may be:

- How the factory labels semi-finished products/finished products.

- Whether the products are exposed to air without coverage

Training, Knowledge, Skill, and Experience

The inspector will assess the company’s training system and procedures, knowledge, and skills, as well as the experience of the factory’s employees. Key attention points may be:

- Does the factory implement training procedures?

- What are the QC inspectors knowledge for their assigned work?

Inspection/Testing and Quality Control

The factory’s quality control management systems and procedures will be evaluated. These include checking the inspection and testing methods of products, as well as maintenance and calibration of inspection/measuring tools. Key attention points may include:

- Inspection and testing stations to evaluate products before release.

- The procedures of in-process inspection and testing.

- The measurement and testing equipment used in inspections.

Documentation of Management/Records Control

The inspector will examine the factory’s documentation and record-keeping procedures.For example:

- Factory’s quality control records.

- Production records.

- Management manuals.

- Document for responsibilities and tasks.

Managers in High-Level

Finally, the skills and experience of the factory’s senior management team are evaluated, as well as their attitude and treatment of customer complaints.

Interested to see the factory audit report in this article? Contact us today to get a free sample of the valve factory audit!

What is the Difference Between a Factory Audit and a Quality Inspection?

While both factory audits and quality inspections are essential, they differ in their focus.

A factory audit evaluates a supplier’s capabilities, including production processes, facilities, and management systems. On the other hand, a quality inspection focuses on specific product batches and involves product sampling/testing.

It’s important to note that although factory audits indicate a supplier’s capability to meet your quality standards, they don’t guarantee that the products will conform to your specific standards. Therefore, conducting a quality inspection after production is recommended to verify whether the produced goods meet the necessary quality requirements.

Image: Example of corrective actions from a factory audit.

Conclusion

A third-party factory audit help businesses reduce risks associated with new suppliers. These audits will give you an unbiased evaluation of your supplier’s capabilities and an idea of whether they can produce goods that meet your quality standards.

If you want to evaluate a new supplier, don’t hesitate to reach us. We offer factory audit in China, India, the United Arab Emirates, Vietnam and 80+ other countries. Contact us today to learn more.