A vehicle comprises of many components: car bodies, chassis, tires, closures, brakes, modules, among others. Given the complexity of automotive manufacturing, where elements from brakes to steering systems are pivotal to a vehicle’s function, precision is paramount.

Third-party inspections of automotive parts provide an added layer of assurance, potentially shielding manufacturers and suppliers from the financial and reputational repercussions of recalls, legal liabilities, and warranty claims. This article presents an overview of a basic inspection checklist employed for automotive parts prior to shipment.

Understanding the Importance of Third-Party Automotive Parts Inspections

Automotive manufacturing, by its very nature, is intricate. Components, whether they’re brakes, steering systems, or any other part, play crucial roles in a vehicle’s operation, leaving no room for inconsistencies. The failure of even a single component can have dire consequences.

Manufacturers undoubtedly have their internal quality control mechanisms. However, using third-party inspections on automotive parts brings about a more comprehensive review, offering an additional layer of reliability. Such inspections can help you to not only meet the stringent regulatory standards imposed by countries on automotive components but also ensure that consistency is maintained across production batches.

Third Party Automotive Parts Inspection Checklist

HQTS possesses years of experience in performing inspections across a diverse array of spare parts. Now, it’s important to highlight that the procedures of an inspection checklist might vary based on the specific product under examination and requirements by the client.

In this article, we’ll delve into the Spring-pad spreader/clip – pad locating product, which is a small component integral to numerous disc brake systems. If you’d like to learn about other parts, we’ve also covered the imported tyres inspection procedures in an earlier article.

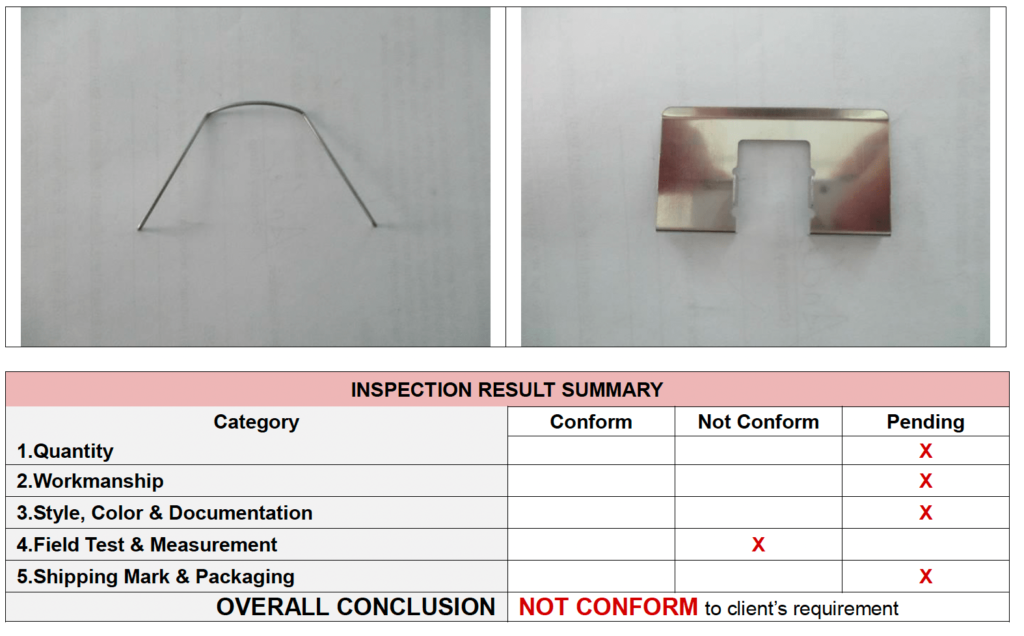

1. Quantity Verification

The first step is often for the inspector to verify the alignment between the number of parts supplied or manufactured and the quantities detailed in orders, delivery notes, or pertinent documentation.

2. Workmanship

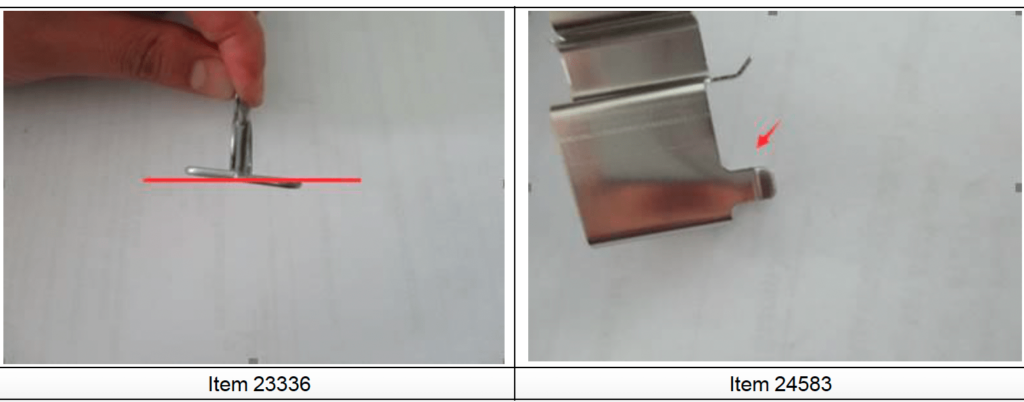

A core facet of third party inspection process is the assessment of automotive spare parts’ workmanship. The techniques employed for this evaluation might vary based on the product under scrutiny.

In this specific assessment, the craftsmanship was predominantly appraised through a visual inspection of the automotive parts. The product must display an impeccable finish, free from overt defects such as dents, scratches, or any blemishes.

Example: If the surface of a spring-pad spreader shows rust or pitting, it might indicate poor material quality or inadequate storage conditions.

3. Style, Color & Documentation

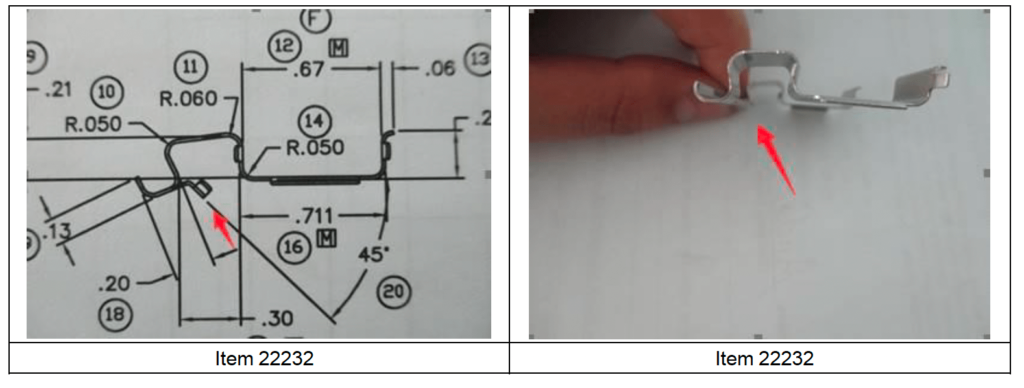

It’s crucial the product’s physical design, including its shape and structure, aligns with the specifications documented or agreed upon. As any deviations could result in functionality challenges, aesthetic inconsistencies, or fitting concerns, particularly in precision sectors like automotive components.

During this inspection, the inspector verified whether the product’s physical appearance matched that which was agreed upon or presented in the prototype or product documentation.

4. Field Test & Measurement

The inspector employs precision-calibrated instruments, or in this scenario rulers, to measure and confirm the dimensions of the automotive parts. The products are also weighed using scales.

All recorded measurements must adhere to the defined tolerance thresholds to guarantee ideal fit and performance. Concurrently, the inspector examines pertinent documentation, such as material test reports, to validate the quality the materials used in the product.

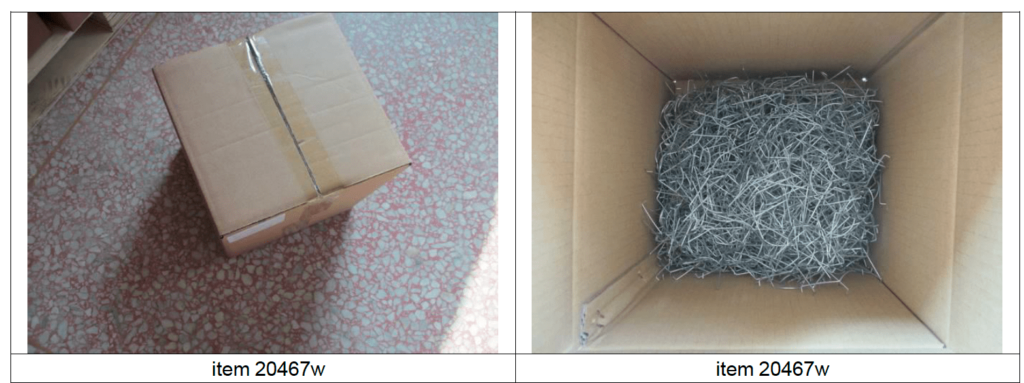

5. Shipping Mark and Packaging

The concluding step involves assessing the packaging’s structural integrity to ensure its suitability for transit. Evaluations extend to the internal protection mechanisms, seals, and closures to confirm their efficacy. The uniformity of packaging, the accuracy of handling labels, and adherence to transportation dimensions are also verified.

Conclusion

Automotive parts inspections are important for ensuring vehicle reliability and safety. Given the intricacies of automotive manufacturing, thorough verification of parts quality is essential. Third-party automotive parts inspections by HQTS involve a series of criteria, including quantity, workmanship, documentation, physical validation, and packaging checks.

Keep in mind that specific checkpoints might vary based on the product. Whether you need automotive parts inspections or sorting services, or simply wants a better understanding of our automotive parts inspection procedures, please reach out to HQTS.