What are PFAS?

PFAS are synthetic chemicals found in everyday products like non-stick cookware, waterproof clothing, food packaging, electronics, and personal care items. They’re super useful because they resist heat, water, and oil, but there’s a big downside: they don’t break down easily.

This means over time, they can spread through water, air, and soil, building up in the environment and even in wildlife – which is why they’ve been labeled “forever chemicals.” Cleaning them up is expensive and really tricky, and exposure has been linked to some serious health issues like cancer, immune problems, reproductive issues, high blood pressure, and thyroid disease.

Because of these risks, regulations on PFAS are tightening fast.

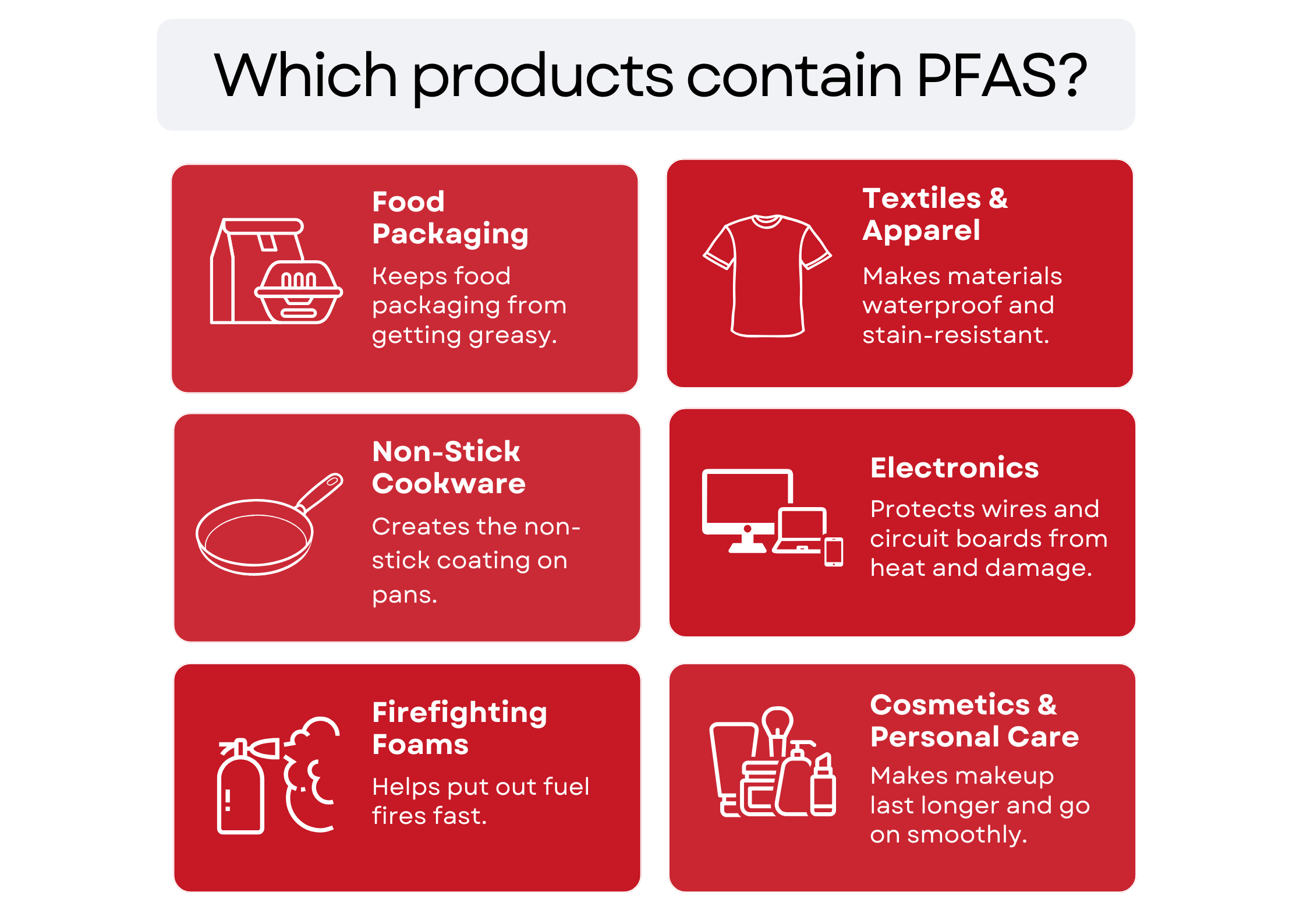

Which products contain PFAS?

- Food packaging – PFAS are used in grease-proof wrappers, fast-food boxes, and microwave popcorn bags to keep oil and water from soaking through. The problem is these chemicals don’t break down and can end up in food.

- Textiles & apparel – PFAS make clothes and fabrics waterproof, stain-resistant, and more durable. You’ll find them in rain jackets, outdoor gear, carpets, and upholstery. Older versions contained long-chain PFAS, which have been linked to health risks. Now, many brands are being forced to phase them out and develop PFAS-free water-repellent coatings.

- Non-Stick cookware – Teflon (PTFE) gives non-stick pans their slick surface. While PTFE itself is stable, older versions used PFOA, a PFAS chemical that contaminated water supplies. That’s been banned, but concerns still linger.

- Electronics – PFAS help keep electronics from overheating and breaking down. They insulate cables, protect circuit boards, and are used in semiconductor manufacturing. These chemicals make electronics more reliable, but they also make them harder to regulate.

- Firefighting foams – AFFF (aqueous film-forming foam) was widely used to put out fuel fires, especially at airports and military bases. It worked well but left behind a toxic mess, contaminating soil and water.

- Cosmetics & personal care – Some waterproof mascaras, long-wear foundations, and even dental floss contain PFAS for a smoother texture and longer wear.

How to test for PFAS

Accredited testing companies like HQTS typically use two tiers of testing: total fluorine screening to flag any fluorine-containing substances (as a proxy for PFAS), and specific PFAS quantification to identify and measure individual PFAS compounds.

We’ll explain both of these below.

Total Fluorine Tests: The quick way to screen for PFAS

Total fluorine (TF) and total organic fluorine (TOF) tests check if fluorine is present in a sample. They don’t tell you exactly which PFAS chemicals are there, but they give you a quick yes-or-no answer on whether fluorinated substances are present above a certain level.

One common method is Particle-Induced Gamma Emission (PIGE), which scans the surface of materials like paper and textiles without destroying them. It’s fast and accurate for detecting fluorine coatings, but it only measures what’s on the surface—so if PFAS are inside the material, it might miss them.

A more thorough method is Combustion Ion Chromatography (CIC). This test burns the sample, turning fluorinated compounds into fluoride, which is then measured. Unlike PIGE, it checks the entire sample, not just the surface.

The downside is that CIC destroys the sample and can’t tell the difference between PFAS and other fluorinated chemicals.

Total fluorine tests are great for broad screening, but they aren’t perfect. Most labs use 100 parts per million (ppm) of total fluorine as a threshold—if a material has more than that, it’s likely been treated with PFAS.

This makes total fluorine tests useful for flagging PFAS in things like food packaging or textiles. However, they may not detect very low levels of contamination.

How much does a total fluorine test cost?

Total fluorine tests are a cost-effective first step. PIGE and CIC tests typically cost a few hundred dollars per sample. Some simpler methods, like ISE, are even cheaper. Many companies start with total fluorine screening for large batches, then follow up with more detailed PFAS testing only when needed.

Targeted PFAS Testing

If you need to know exactly which PFAS chemicals are in your sample, you’ll need targeted analysis. This method identifies individual PFAS compounds and measures their levels. The go-to technique is liquid chromatography with mass spectrometry (LC-MS/MS), which separates and detects specific PFAS chemicals based on their unique mass.

Labs can test for anywhere from 18 to over 100 different PFAS, depending on the method. For example:

- EPA Method 537.1 tests for 18 PFAS in drinking water.

- EPA Method 533 covers 25 PFAS.

- EPA Method 1633 (still in development) will detect around 40 PFAS in various sample types.

Even the most advanced tests can only detect a fraction of the 12,000+ known PFAS chemicals, so they might miss newer or uncommon ones.

These tests are reliable, but they only find PFAS that are specifically included in the test list—anything outside of it goes undetected.

How much does Targeted PFAS testing cost?

Targeted PFAS testing is more expensive than total fluorine screening. A standard LC-MS/MS test costs anywhere from $400 to $700 per sample, depending on the number of PFAS tested. Costs increase if more compounds or complex materials are involved.

Advanced testing for hidden PFAS

If you suspect there are PFAS in your product but don’t know which ones, there are advanced methods that go beyond standard targeted testing.

- Total Oxidizable Precursor (TOP) Assay: This test reveals hidden PFAS by oxidizing precursors into detectable end-products like PFOA. It’s useful for testing things like firefighting foam and wastewater.

- Non-Targeted Analysis (HRMS): High-resolution mass spectrometry (LC-QTOF-MS) can scan for a wide range of fluorinated chemicals, even if they aren’t on standard PFAS test lists. This is useful for identifying unknown PFAS, but it’s expensive and mainly used in research.

PFAS testing for products, food and water

PFAS in Food

PFAS testing for food works by extracting PFAS from the food and measuring 16 specific compounds.

This method can detect PFAS at extremely low levels, sometimes down to single-digit parts-per-trillion (ppt), depending on the type of food. Testing labs adjust the process for different foods, like meat and eggs, to ensure accuracy.

The process typically involves:

- Blending the food into a uniform sample

- Extracting PFAS using solvents

- Removing fats and proteins to prevent interference

- Using isotope-labeled standards for precise results

PFAS in food packaging

For food packaging, certified labs like HQTS usually start with a total fluorine screening test to check for possible PFAS. This involves burning the sample and measuring fluorine levels.

- Low TOF levels (under 100 ppm) suggest no intentional PFAS use.

- High TOF levels indicate PFAS may have been added, requiring further testing.

If contamination is suspected, labs can conduct more detailed tests to identify specific PFAS compounds.

PFAS testing in products

PFAS chemicals are found in many everyday products, from clothing and electronics to plastics and firefighting foams.

As explained earlier, most PFAS testing follows a two-step approach: first, a total fluorine screening checks for any fluorinated substances, and if needed, targeted analysis identifies specific PFAS compounds. Total fluorine tests like PIGE and CIC provide a broad screening, while LC-MS/MS pinpoints individual PFAS chemicals with high precision.

For cases where standard tests might miss hidden PFAS, advanced methods like the Total Oxidizable Precursor (TOP) assay or high-resolution mass spectrometry can uncover unknown or precursor compounds. These techniques help businesses detect PFAS contamination and comply with evolving regulations. The best testing method depends on the type of product, the level of detail required, and industry standards.

PFAS testing for water

PFAS can enter water supplies through industrial waste, firefighting foam, and contaminated soil.

The most reliable way to detect PFAS is LC-MS/MS, which can find even tiny amounts in drinking water. But as with food and product testing, some labs start with total fluorine screening to check for fluorinated substances. If levels are high, further testing is done to confirm the presence of PFAS.

For detecting hidden or precursor PFAS, labs may use TOP assay and other advanced methods, particularly when testing wastewater or landfill runoff.

Which countries require PFAS testing in 2025? (or will soon)

United States (Federal & State)

Starting in 2025, manufacturers in the US must report any PFAS made or imported since 2011 under new TSCA reporting rules. The EPA is also adding nine more PFAS chemicals to the Toxics Release Inventory, bringing the total to 205, and removing exemptions for reporting low concentrations.

A new “Significant New Use Rule” (SNUR) blocks companies from reintroducing PFAS that have been inactive since 2006 without prior EPA approval. Additionally, the EPA is pushing to classify some PFAS as hazardous substances and set near-zero drinking water limits for PFOA and PFOS, with stricter thresholds for other PFAS like PFBS and GenX.

States are moving even faster. California and New York will ban PFAS in apparel by 2025, targeting their use in waterproof clothing. Several states, including California, Colorado, Maryland, and Vermont, have already banned PFAS in food packaging and children’s products.

Starting January 2025, California, Colorado, and Minnesota will prohibit intentionally added PFAS in cosmetics. Maine now requires manufacturers to disclose PFAS in all products sold in the state, forcing companies to test and report their supply chain data. Many states have also banned or restricted PFAS in firefighting foams.

European Union (EU)

The EU has already banned some of the most harmful long-chain PFAS under its persistent organic pollutants (POP) regulation. PFOS has been restricted for over a decade, and PFOA, along with related chemicals, is largely banned except for trace contamination. These restrictions are in line with the Stockholm Convention, which EU countries enforce.

A much broader PFAS ban is on the horizon. In 2023, five EU countries proposed a sweeping PFAS restriction under REACH, which could take effect around 2025–2026. If approved, it would limit thousands of PFAS chemicals in most applications, with only a few exceptions for essential uses.

Meanwhile, the EU is updating drinking water limits—by 2026, any single PFAS will be capped at 0.1 µg/L, and total PFAS levels will be limited to 0.5 µg/L. New rules for food contact materials are also in the works and may include PFAS bans in food packaging.

Although the UK is no longer part of the EU, it is closely following EU regulations. The UK is considering its own broad PFAS ban and has strengthened water monitoring for PFAS contamination. Norway and Switzerland, despite being outside the EU, also enforce strict PFAS regulations. Norway was one of the first countries to ban PFOA in consumer products back in 2014.

Under REACH, each EU country enforces PFAS rules in its own way. Penalties can include fines, product seizures, and even criminal charges in serious cases. Selling a banned PFAS-containing product in the EU could result in multimillion-dollar fines and mandatory recalls. Companies must conduct thorough testing and supplier audits to stay compliant with both current and upcoming regulations.

Other Major Regions

Canada is tightening PFAS oversight. In 2024, Health Canada introduced new drinking water limits for multiple PFAS and is working on formal regulations. Canada is also considering broad PFAS restrictions in products, aligning with the EU’s approach.

Asia-Pacific countries are gradually increasing PFAS regulations. Japan, South Korea, and China follow the Stockholm Convention, which bans PFOS, PFOA, and related substances in many applications. China restricts PFOS and PFOA in textiles and monitors PFAS levels in water. Australia has issued drinking water guidelines and is phasing out PFAS-based firefighting foams. New Zealand and several other countries have also imposed import restrictions on PFAS-containing products.

On a global level, PFAS are being added to the Stockholm Convention on Persistent Organic Pollutants (POPs), requiring signatories to eliminate listed PFAS except for essential uses. The OECD is pushing for standardized international PFAS regulations. With new restrictions taking effect in 2025 and beyond, companies operating globally need to stay ahead of these changes to avoid supply chain disruptions and compliance risks.

How to comply with tightening PFAS regulations

With PFAS regulations tightening, companies need a clear plan to stay compliant and keep their supply chains clean.

- The first step is figuring out where PFAS are showing up in your products. That means auditing suppliers and making them disclose any PFAS use in materials, coatings, or packaging. Many companies are already sending out supplier surveys and finding PFAS in places they didn’t expect—like adhesives in shoes.

- Next, it’s about finding alternatives. Some industries are ahead of the game—outdoor brands are switching to PFAS-free water repellents, food packaging companies are moving to plant-based coatings, and cookware manufacturers are replacing Teflon with ceramic.

In the past, some of these alternatives didn’t work as well, but that’s changing. Silicone-based coatings, for example, now perform almost as well as PFAS-based ones.

- Testing is another key step. Even if you remove PFAS from your materials, contamination can still happen. Standard tests look for specific chemicals like PFOA and PFOS, but since there are thousands of PFAS compounds, broader screening methods are becoming more common.

Many companies now test for Total Organic Fluorine (TOF), since fluorine is a sign that PFAS might be present. If fluorine is detected, more detailed lab tests can identify exactly what’s in the product. Regular testing of raw materials, finished goods, and packaging helps catch problems early—before they become regulatory or customer issues.

- It’s also important to remember that compliance isn’t a one-time fix. Regulations are changing fast. When a new ban is announced—say, a country decides to outlaw PFAS in firefighting gear by 2026—compliance teams can flag it early so product designers and suppliers have time to adjust.

- Documentation is just as important. If regulators start asking questions, having supplier disclosures, lab test results, and internal audits ready can make all the difference. Training employees is also crucial—procurement, R&D, and manufacturing teams need to know what to avoid so they don’t bring PFAS back into the supply chain by accident.

How HQTS can help with PFAS compliance and testing

Keeping up with PFAS regulations can be challenging, but we’re here to help. HQTS labs in Asia are fully accredited for PFAS testing.

Our experts test for restricted PFAS chemicals under EU and US standards, ensuring your products meet the latest requirements. We can also check for PFAS in chemical formulations, including those banned in textiles, leather, and footwear production.

Beyond testing, we work with businesses to navigate PFAS regulations and reduce financial risks. With a global network of accredited labs, HQTS provides reliable testing, certification, and expert guidance—so you can stay compliant with confidence.

To find out more about our PFAS testing and compliance services contact our team today.