For businesses importing tyres from overseas, especially from Asia, verifying the product quality before shipment is important. But this can be challenging, especially when you tyre supplier is located thousands of miles away in countries like China, Thailand, or Japan.

Many importers turn to third-party inspection services to verify the quality of their tires. In this guide, we’ll go through the tire inspection criteria that impartial inspectors, such as those at HQTS, employ to verify the quality of imported tyres.

What are the Common Quality Defects in Imported Tyres?

Importing tyres can be a financially beneficial option. However, this benefit can quickly dissipate if you’re unfortunate to deal with unreliable or deceitful suppliers. A crucial initial step is confirming the legitimacy of your chosen supplier and verify that they are licensed for the type of business that they are claiming to be operating in using a supplier audit or factory audit.

Below are some of the prevalent defects our team often uncovers during tyre inspections:

- Quality of Rubber: Inconsistencies in rubber quality, usage of subpar rubber, or insufficient rubber content.

- Flat Tires: Tyres that don’t maintain their shape or pressure.

- Incorrect Dimensions: Tyres not adhering to stipulated product specifications.

- Regulatory and Labeling Discrepancies: Mislabeling, missing critical data like manufacturing dates, or non-compliance with essential standards, e.g., the U.S. DOT or Europe’s E-Mark.

Tyres Inspection Checklist

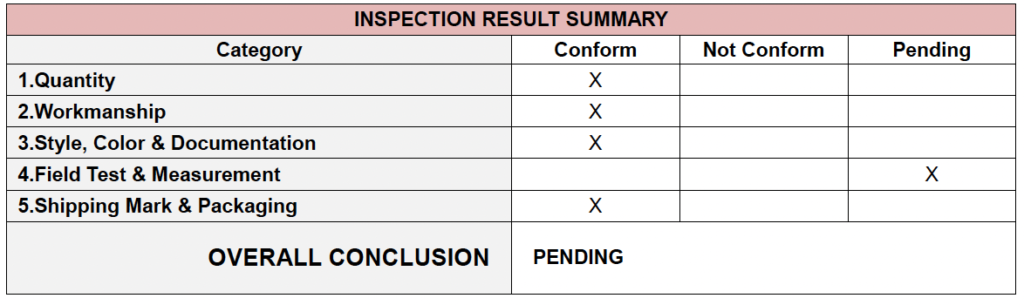

With extensive experience in inspecting automotive parts, including tyres, HQTS inspectors follow a detailed checklist to identify potential defects, minor or significant. While the simplified tyre checklist in this article will give you a general idea, it’s important to note that the inspection criteria is often customised based on specific requirements.

Here’s a general rundown of our approach:

1. Quantity Verification

The primary goal of the quantity verification of tires is to check that total number of tires in the shipment matches the quantity specified in the purchase order or shipping documentation.

2. Workmanship

The inspector would then search for manufacturing defects through a visual examination of each tire. For example, to spot subtle issues like moulding flash, which, if left unchecked, could impact the tire’s performance. Detailed photographs and notes are taken for clear documentation in the reports.

3. Style, Color, and Document Verification

Inspectors verify that tires match provided specifications, from tread style to color. By comparing them to the purchase order, product specifications, and reference photos.

Additionally, if applicable, the inspector will evaluate the factory’s self-test report, as it will give an indication of the batch’s adherence to internal quality benchmarks.

4. Field Test and Measurement

The physical characteristics of the tyre are also assessed by the inspector. Using precise tools, including rulers and weighing scales, inspectors check each tyre’s dimensions and weight against the product specifications. Additionally, the barcode on each tyre is scanned and cross-referenced with a database or the buyer’s records to ascertain the product’s authenticity.

5. Shipping Marks and Packaging

Lastly, the inspector will verify that the tires have stickers on the surface of the products and check the packaging condition.

Conclusion: Guide to Third Party Inspection for Imported Tyres

In this article, we have outlined the five main dimensions our inspectors consider during a third-party tyre inspection. Specifically, these are quantity verification (ensuring alignment with product specifications), workmanship (evaluating the overall quality of the tyres), style, colour, and document verification (confirming the tyres match the product specifications), and field tests or measurements (assessing the dimensions, weights, and verifying the product’s authenticity), shipping marks and packaging.

It’s important to understand that the specifics of each inspection can differ based on the particular tyre in question and the client’s unique requirements. If you require an inspection for your imported tyres, do not hesitate to get in touch with us.