India has been a manufacturing country for centuries, renowned for its textiles, metalwork, ceramics, and not to mention the hard goods industry. Although the country offers a great selection of suppliers, there are prevalent challenges with consistent quality.

One effective method to reduce quality risks when you’re sourcing is by performing product inspections in India. This article will cover the key aspects of a typical quality inspection in India.

Understanding Product Inspection in India

Product inspection in India is a quality control method businesses employ to examine their goods’ quality, safety, and compliance. Inspections happen at several stages of the production cycle, including:

- Before Production Inspection (PPI)

- During Production Inspection (DUPRO)

- Piece by Piece Inspection (PI)

- Container Loading/Unloading Inspection (CLC)

But the most common one is performed before shipment.

Due to budget constraints and the lack of in-house expertise, businesses often lean towards local third-party inspection agencies in India for product inspection.

The Importance of Product Inspections in India

It’s always a good practice to assess the quality of products at their country of origin factory. This helps ensure that the products align with the agreements between you and the Indian manufacturer and meet the required quality standards.

But India’s unique features set it apart from other manufacturing nations:

- Diverse Manufacturing Practices: India boasts a mix of modern and traditional manufacturing practices, leading to varying production standards.

- Regulatory Standards: The country has its set of regulatory standards and requirements.

- Complex Supply Chain: India’s vast geography contributes to its highly diversified and complex supply chain.

- Manufacturing Base: India’s manufacturing base is a mix of family-owned local producers to large-scale multinational corporations.

- Unique Products: Certain manufacturers may have a majority of the production process performed by hand, leading to unique, handmade products and variations in quality.

Product Inspection Checklist in India

At HQTS, we conduct product inspections across India. While the criteria for each inspection may vary depending on the inspection stage, product category, or client requirements, we usually check several key dimensions.

Here’s a recent furniture quality inspection in India where our inspector had a series of remarks.

1. Quantity Verification

Our inspectors first verify the quantity. That means they’ll count the number of goods ready for shipment to ensure they match your purchase order. Below is an example of a quantity verification that display the inspected quantity and number of defects.

2. Workmanship

The next step involves assessing the workmanship of the products. This process includes comparing the furniture to the agreed-upon design and checking for visible damages like broken edges, scratch marks, or broken legs.

The inspector will also assess material quality, evaluate the sturdiness of the furniture’s joints, screws, and other hardware, test moving parts like drawers, doors, or reclining mechanisms, and evaluate the overall appearance.

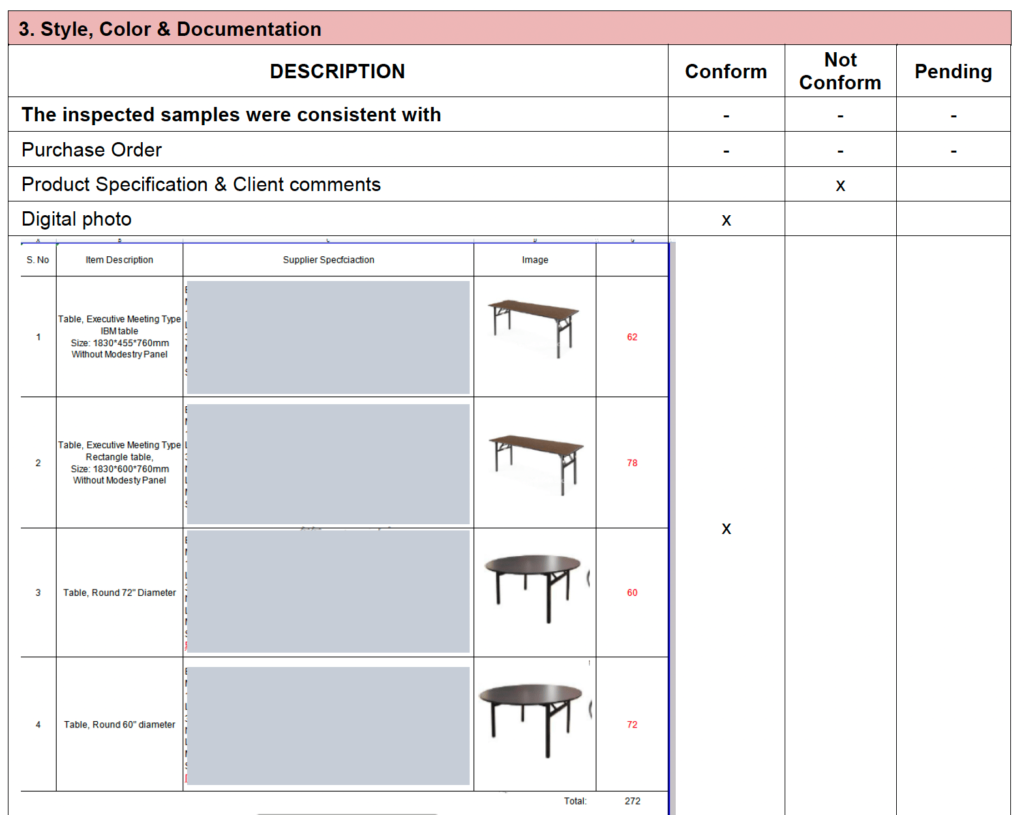

3. Style, Color & Documentation

Inspectors then check the items against the purchase order, product specifications, client requirements, and other relevant documentation.

4. Field Test & Measurement

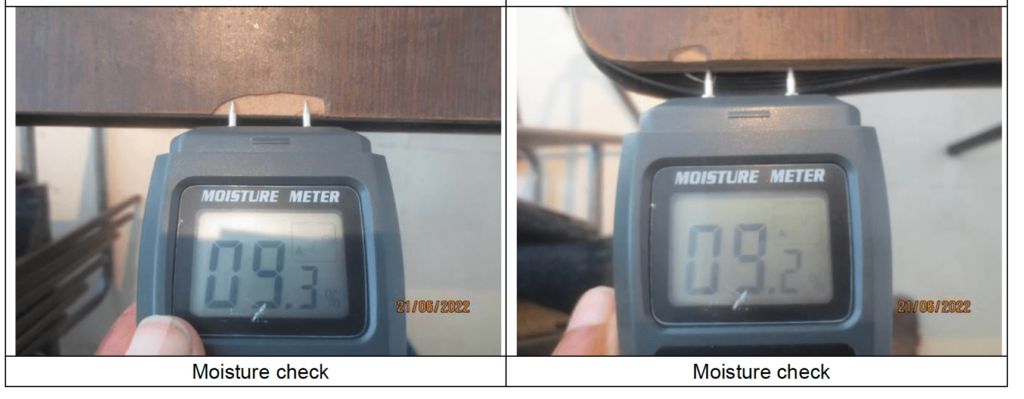

Lastly, the inspector performs various tests on the inspected items. These vary depending on the product category and client requirements and may include smell checks, size measurements, appearance checks, moisture content checks, and function checks.

Conclusion: Verifying Quality with Product Inspections in India

Product inspections in India are cost-effective to verify that your products adhere to your quality standards. It’s important to note these inspections can be carried out at various stages in the production cycle, and the checklist can differ depending on the product being inspected.

In this article, we outlined the key elements of a furniture inspection in India, including quantity verification, workmanship assessment, documentation verification, and field test and measurements.

HQTS has been in India since 2006, with a local office in Delhi and our own inspectors. We offer factory audits in India and inspection services throughout the country. If you have any inquiries regarding quality inspections in India, please don’t hesitate to contact us.