The global electric scooter market is experiencing substantial growth as governments worldwide prioritize cleaner and more efficient transportation solutions. With a projected value of USD 34.91 billion by 2030 and a CAGR of 7.00% from 2023 to 2030, the market is set to expand significantly. Governments are investing in charging infrastructure and providing incentives to buyers, presenting opportunities for OEMs to expand their revenue streams and geographic presence.

In the Asia Pacific region, the demand for energy-efficient electric two-wheelers is driving steady market growth, while the North American market is experiencing rapid expansion, especially in the high-performance E-Motorcycle segment. Challenges such as the lack of charging infrastructure, high initial costs, and performance limitations could hinder the global market’s growth. Nonetheless, the overall trend points towards a promising future for the electric scooter and motorcycle market.

Besides, the e-scooter industry presents manufacturers and importers with the challenge of navigating complex and constantly evolving regulations. To guarantee quality, safety, and compliance, manufacturers and importers are increasingly turning to third-party quality partners such as HQTS, we can assist in navigating the intricate landscape of market regulations and ensure the products’ quality and safety.

Quality Inspections for E-Scooters

As the popularity of e-scooter continues to rise, ensuring their quality and compliance with industry standards becomes crucial. To guarantee the highest level of quality control, companies often employ reputable inspection agencies such as HQTS. There are, in total, 4 types of inspection in quality control: pre-production inspection, during production inspection, pre-shipment inspection, and container loading/unloading inspections.

Today let’s look into the key aspects involved in conducting a Pre-Shipment Quality Inspection of a E-Scooter factory in China. During this specific inspection, the HQTS inspector, as per the client’s requirements, focused on the next items:

Quantity

Discrepancies in batch quantities can cause confusion, delays, and inventory tracking issues. Our inspection team conducts a thorough count and cross-checks of e-scooters ready to be delivered against purchase order documentation. They compare the shipment’s quantity to the specified order quantity, ensuring precise alignment between the two. This meticulous process guarantees accurate documentation and facilitates smooth inventory management.

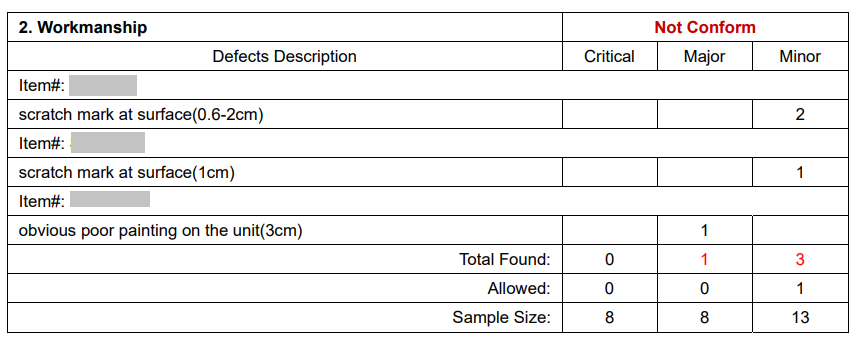

Workmanship

After the quantity verification, the inspector will visually inspect the exterior and interior parts of the e-scooter. They’ll check for the following aspects, including:

- Scratch marks, dirt marks, abrasion

- Defective parts

- Identify any visible defects, such as rust or metallic luster, substandard surface coating, or oil stains.

- Verification that the structure assembly aligns with the provided drawings.

- Other

*All our reports come with high quality pictures of the detected issues

*All our reports come with high quality pictures of the detected issues

Style, Color & Documentation

This typically includes reviewing the presence and accuracy of the Purchase Order, Product Specification, and User Manual. These documents provide essential information about the product, its specifications, usage instructions, and any other specific requirements requested by the client. Besides HQTS will review other specific questions around the documentation provided by the client.

Field Test

The inspection service provided by HQTS for e-scooters in the Pre-shipment inspection report includes a comprehensive range of tests and checks to ensure the quality and performance of the products. Here are the specific tests and checks conducted:

- Switch Life Check: This test evaluates the durability and lifespan of the switch by repeatedly turning it on and off to ensure its proper functioning.

- Working Current Check: The working current of the e-scooter is measured to ensure that it falls within the specified range and is functioning correctly.

- Battery Capacity Check: The capacity of the battery is assessed to verify that it meets the specified requirements and can provide sufficient power for the e-scooter’s operation.

- Loading Check: This check examines how the e-scooter performs when subjected to a specified load or weight capacity to ensure it functions properly under normal operating conditions.

- Battery Initial Voltage Check: The initial voltage of the battery is measured to ensure it meets the specified level and can provide adequate power for the e-scooter.

- Motor Speeds Check: The speed of the motor is assessed to ensure it operates within the specified range and provides the desired performance, this also includes related checks like motor heat dissipation test.

- Assembly Check: The assembly of the e-scooter is inspected to verify that all components are correctly assembled and securely fastened.

- Power Consumption Check: The power consumption of the e-scooter is measured to ensure it falls within the specified limits and is energy-efficient.

- Product Performance Check: The overall performance of the e-scooter is evaluated, including aspects such as acceleration, braking, stability, and handling.

- Length of Power Cord: The length of the power cord is measured to confirm it meets the specified requirements.

- Hi-Pot Test: This test checks the electrical insulation of the e-scooter by applying a high voltage to detect any potential electrical issues or safety hazards.

- Waterproof Testing: The e-scooter undergoes testing to assess its resistance to water and verify its waterproof capabilities, this includes some specific tests like the water resistance test (IP67) and more

- Other tests requested by our clients

By conducting these tests and checks, HQTS ensures that the e-scooters meet the necessary quality standards, perform reliably, and comply with safety requirements, providing confidence to both manufacturers and consumers.

Measurement

It involves verifying the dimensions of the e-scooter to ensure they meet the specified requirements. Here’s an overview of how the product dimension check is conducted:

- Measurement of Length, Width, and Height

- Wheelbase Measurement

- Handlebar Height Check

- Weight Measurement

- Folded Dimensions (If Applicable)

Shipping Mark and Packaging

The Shipping Mark and Packaging service in HQTS pre-shipment inspections for e-scooters includes an evaluation of the labeling and packaging aspects of the products. It includes the next items:

- Shipping Mark Verification

- Packaging Condition Check

- Labeling Verification

- Packaging Compliance

The importance of E-Scooter Quality Inspections

In conclusion, conducting professional third-party quality inspections for e-scooters is crucial for ensuring product integrity, safety, and customer satisfaction. Throughout this article, we have explored the essential steps involved in these inspections, emphasizing the importance of engaging a reliable third-party inspection service like HQTS. By prioritizing professional third-party quality inspections, manufacturers and importers can foster consumer trust, meet regulatory obligations, and ultimately succeed in the competitive e-scooter market. Don’t leave the success of your e-scooter business to chance. Contact us today to learn more about our comprehensive inspection services and how we can help you ensure the quality and compliance of your e-scooter products.